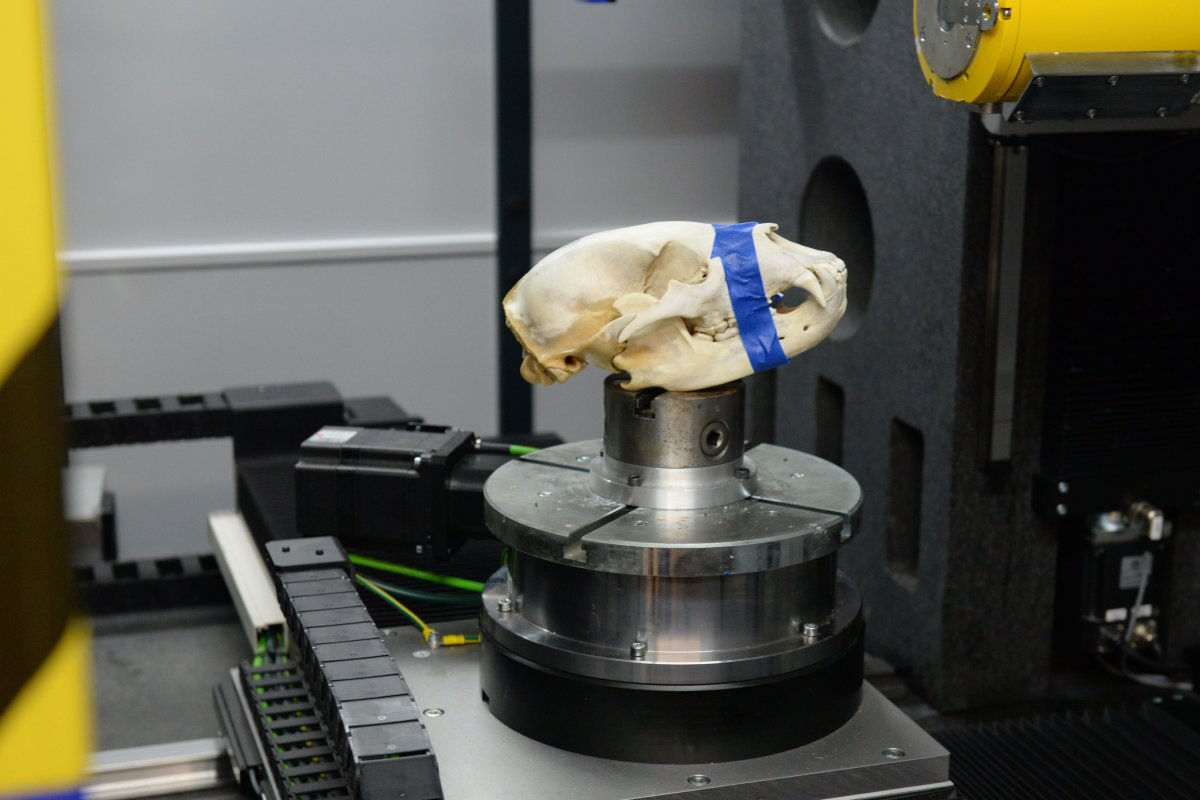

The Center for Quantitative Imaging (CQI) provides high-resolution X-ray computed tomography (CT) and advanced non-destructive testing to help industry partners visualize internal structures, quantify material properties, and solve complex quality and performance challenges.

The technology of microCT scanning creates high-resolution three-dimensional 3D images by using x-rays. To do this, the microCT scanner collects two-dimensional (2D) trans-axial projections (or slices) of the scanned material/specimen. Once collected, the slices are then reconstructed into a full 3D model.

Lab technicians work closely with clients to understand the objectives and offer the best possible solutions, collaborate on the process, and deliver the finest images.

Computed Tomography Users Group

Join the Penn State Computed Tomography (CT) Users Group, hosted by the Center for Quantitative Imaging (CQI). CT is a powerful imaging technique that creates high-resolution 3D images of anything from delicate fish specimens to complex electronics. This allows for a non-destructive examination of internal structures, providing valuable insights into their composition and function.

Work with Us

The Center for Quantitative Imaging is available to assist both Penn State researchers and external clients from industry, government, and other universities. Get started:

Join the CT Users Group

This group is open to faculty, students, and researchers across all Penn State campuses who are interested in harnessing the power of computed tomography for their work.

Core Capabilities

Techniques

- High-resolution microCT

- Industrial CT scanning

- 3D volume reconstruction

- Digital segmentation and visualization

- Quantitative image analysis and measurement

What We Measure

- Internal defects, porosity, inclusions, and cracks

- Dimensional accuracy and geometric deviations

- Material distribution, density, and structural uniformity

- Failure modes and degradation pathways

What You Gain

- Accurate, non-destructive insight into internal structures

- Faster troubleshooting of product issues

- Higher confidence in material and component performance

- Data to support R&D, quality control, and regulatory needs

Industries We Serve

Food & Packaging

CQI helps companies evaluate product integrity and optimize packaging performance without compromising samples.

Typical applications:

- Detecting internal packaging defects

- Evaluating food structure for quality and safety

- Confirming barrier integrity and seal performance

- Quantifying stress points and deformation

Materials & Engineered Products

We support R&D and quality assurance for advanced materials where internal structure determines performance.

Typical applications:

- Characterizing porosity and internal flaws in composites

- Validating additive manufacturing and 3D-printed parts

- Assessing structural integrity and failure mechanisms

- Comparing material behavior under different conditions

Coatings, Paints & Chemical Products

Non-destructive imaging reveals how coatings and chemical products interact with substrates—something conventional methods can’t see.

Typical applications:

- Measuring coating thickness and uniformity

- Detecting subsurface defects or delamination

- Analyzing chemical or material distribution

- Supporting formulation and performance testing

Electronics & Consumer Goods

Our imaging systems reveal complex internal assemblies with micron-level clarity to help ensure reliability and safety.

Typical applications:

- Inspecting circuitry, solder joints, and connectors

- Identifying internal manufacturing defects

- Evaluating wear, fatigue, or failure points

- Supporting quality control for complex devices

Construction & Building Materials

3D imaging helps companies understand durability, structural performance, and long-term material behavior.

Typical applications:

- Evaluating concrete porosity and aggregate distribution

- Detecting cracks, voids, and hidden failures

- Measuring reinforcement placement

- Supporting durability and performance studies

Healthcare

CQI supports healthcare, biomedical, and life science partners by providing non-destructive, high‑resolution imaging and quantitative analysis of medical devices, biological materials, and healthcare-related products. Our imaging capabilities enable detailed internal visualization and measurement without altering or destroying sensitive samples, supporting innovation, safety, and regulatory confidence.

Typical applications:

- Evaluating internal structures of medical devices, implants, and components

- Assessing manufacturing quality, dimensional accuracy, and material uniformity

- Detecting internal defects, voids, or misalignments in device assemblies

- Quantifying porosity and structural integrity of biomaterials and scaffolds

- Supporting pre‑clinical research, product development, and failure analysis

Capabilities

In the News

Center for Quantitative Imaging Staff

Address

Center for Quantitative Imaging

416 Academic Activities Building

University Park, PA 16802