In 1987, the Montreal Protocol was designed with the aim to regulate and phase out the global production of ozone-depleting substances such as chlorofluorocarbons (CFCs) that were used in air conditioning, insulations, refrigeration, and other applications. The largely successful CFC phaseout in recent years has been accomplished through the replacement of CFCs with hydrofluorocarbons (HFCs) and has led to the slow recovery of the ozone layer.

While HFCs do not contribute to ozone depletion, they have global warming potentials (GWP) at the magnitude of hundreds to thousands of times higher than that of carbon dioxide. The global warming potential of HFC-134a, commonly used in refrigeration and aerosol propellants, is 1,430, which means its potential to trap the heat in the atmosphere is 1,430 times as much as carbon dioxide over a 100-year period.

Replacing HFCs in the Building Industry

One application of HFCs is in the insulation production industry where they are used as blowing agents to create thermally resistant closed-cell insulation materials. According to the Environmental Protection Agency (EPA), the consumption of HFC as a blowing agent in the building and construction insulation sector accounted for “38 million metric tons of carbon dioxide equivalent in 2010,” 98% of which comes from developed countries. This amount of carbon dioxide emissions is equivalent to the total carbon dioxide emitted by more than 8.2 million average gasoline passenger cars driving 11,500 miles per year. The EPA data also suggests that the spray foams and extruded polystyrene (XPS) boards were the largest HFC consumers in 2010, accounting for 51% and 24% of HFC consumption, respectively.

XPS has a thermal resistance value (i.e., R-value) of 4.7-5 per inch of thickness which makes it an effective material choice to insulate the building walls and roofs. While XPS and spray polyurethane foam insulations reduce the energy that is used in buildings for heating and cooling, the use of HFC-134a and other blowing agents in their production has led to the rebound effect of increasing embodied carbon and global warming potential of buildings.

To address the high contribution of HFCs to global warming, the AIM Act of 2020 enacted by the U.S. Congress directed the EPA to phase down HFC production and consumption. As a result, the EPA is now calling for reducing the production and consumption of HFCs by 85% by 2037. The HFC blowing agents will therefore be replaced by hydrofluoroolefins (HFOs) which have zero ozone-depletion potential, yet an ultra-low global warming potential of 6.

Holistic Approach to Environmental Impacts of Buildings

The example of insulation materials reducing building energy use while increasing embodied carbon, or HFC-based XPS insulations reducing ozone depletion while increasing global warming, demonstrates the need to develop a holistic and multidimensional understanding of the environmental impacts of buildings. Penn State is training the next generation of architects and engineers who have design and analytical skills to create sustainable built environments, understanding the sophisticated interrelations between various aspects of impacts on the environment.

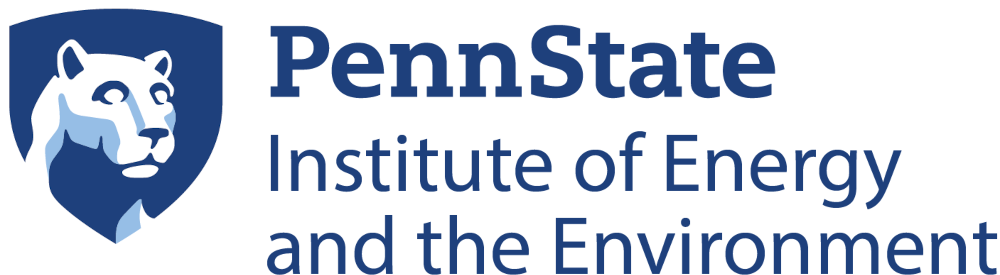

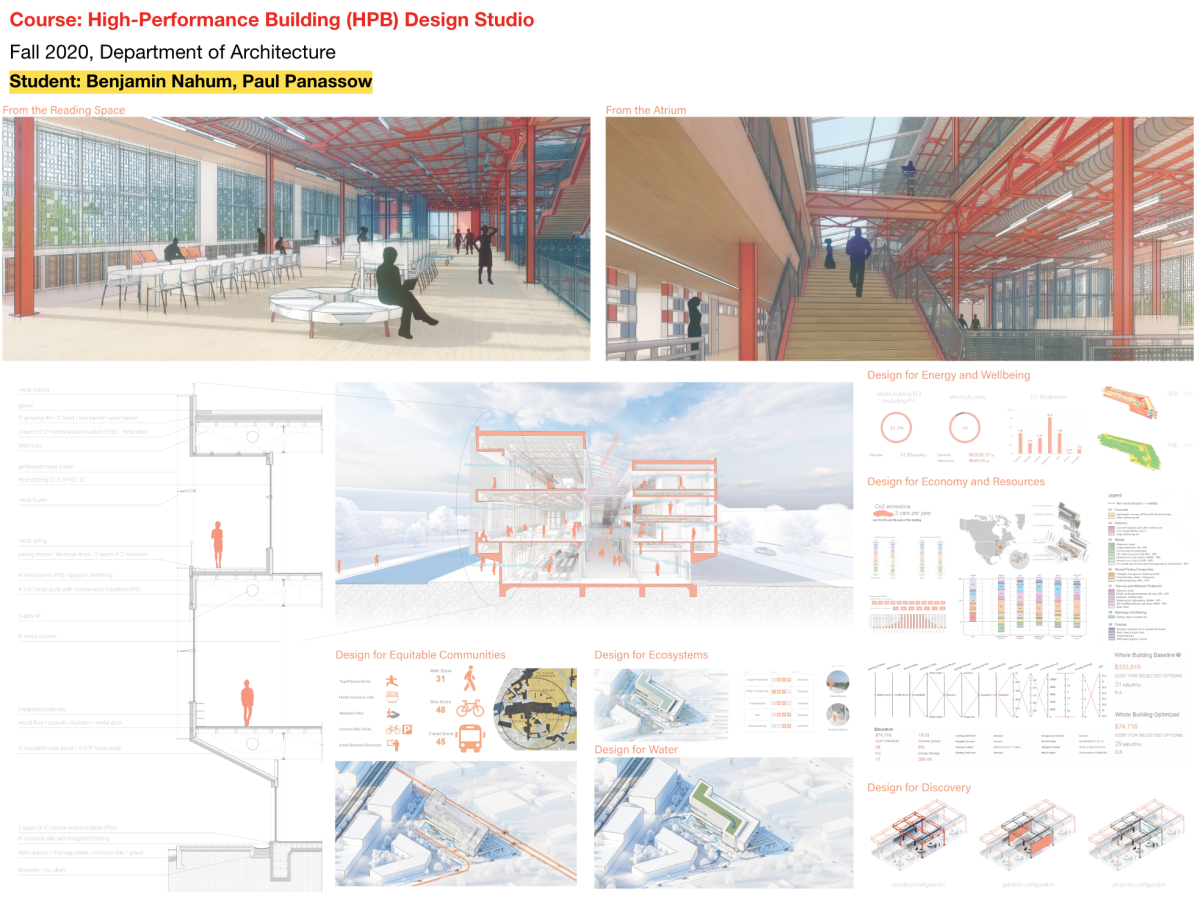

As an example, in the High-Performance Building (HPB) design studio, a Directed Research Studio course* offered in the Department of Architecture, students design low-energy, low-embodied-carbon, and healthy buildings by using a variety of design and simulation skills.

Outside of Penn State, faculty members are starting and supporting groups, such as Carbon Leadership Forum (CLF)-Philly**, that are targeting issues like embodied carbon in insulation.

*The High-Performance Building design studio course in the Department of Architecture is taught by Rahman Azari. Azari's lab is RE2.

**The CLF-Philly was co-founded by Lisa Conway (Interface).com; Esther Obonyo (Penn State), and Cecilia Freeman (EwingCole).