29-minute listen/watch | 21-minute read | 1-minute teaser

Wind power has come a long way from its humble beginnings as water pumps and windmills. Today, it's a major contributor to our electricity generation. While onshore wind farms are well-established, the U.S. has yet to tap into the full potential of offshore wind. With advancements like floating turbines and improved blade designs, wind energy is poised for another significant leap forward.

Transcript

Mark Miller

The Department of Energy in the United States is very pro floating offshore wind platform development because we have such a big resource in the U.S., especially on the West Coast of these deepwater areas where this could be used if it was cheap enough and reliable enough.

Host

Welcome to Growing Impact, a podcast by the Institute of Energy and the Environment at Penn State. Each month, Growing Impact explores the projects of Penn State researchers who are solving some of the world's most challenging energy and environmental issues. Each project has been funded through a seed grant program that's facilitated through IEE. I'm your host, Kevin Sliman.

Wind energy continues to expand and diversify. What started with simple wind-powered water pumps and windmills more than 2,000 years ago, transformed into small wind electric generators by the late 1800s. Today, there are nearly 350,000 wind turbines on Earth. In 2022, the 90,000 wind turbines located in America generated 434 billion kilowatt hours of electricity, contributing to about 10% of the country's total utility scale electricity. However, offshore wind, despite its potential, is largely underdeveloped in the United States.

On this episode of Growing Impact, we discuss the future of wind energy, including floating offshore wind turbines and a shift in turbine blade design that may be a real game changer.

Thank you both for being on Growing Impact. I really appreciate you taking time just to talk about this. Wind energy is a big topic, and I'm interested to learn more about these floating offshore wind turbines. But before we jump into it, can everyone just introduce themselves? Could you tell me your name, title, and provide a brief background on your research?

Mark Miller

Thanks, Kevin. My name is Mark Miller. I'm an assistant professor in aerospace engineering at Penn State. My research area is kind of on the experimental aerodynamics side. And to do that, we have a bunch of different tools at Penn State, one of which is a new wind tunnel facility that we've built actually out at the airport. That's a special form of wind tunnel, called a compressed air tunnel. And we can use that to study kind of all different things.

Right now we're doing a lot of things that rotate. So wind turbines, rotorcraft, but we're also looking at testing airfoils, different kind of unique aircraft configurations potentially that, you know, you might not want to build at full scale, but we can test in our facility, and they essentially act like they're at full scale.

Host

And Sven, welcome back to Growing Impact. This is your second time. The first time we discussed contrails and climate change. And this time we're talking about floating offshore wind turbines. So could you reintroduce yourself to those maybe who didn't hear that episode?

Sven Schmitz

Sure. Yes. And we are still talking about combating climate change, right? So, I'm Sven Schmitz. I'm the Boeing/Welliver Professor here in aerospace engineering. And my work really centers around computational aerodynamics. My students, they... to sum it up easily, they model everything that rotates. So, we look at wind turbine blades, we look at model rotors, we look at helicopters, multicopters, even drones to fly on other planets.

And so really how Mark and I connect is I'm looking at large rotors and it's difficult to model those kind of at full scale and to assess their performance. And so Mark's facility comes in here because he can provide some fluid dynamic scaling conditions where we can kind of tackle this gap in the scales that we have from large machines down to model scale.

Host

So that wind tunnel is helping you, Sven, in your work?

Sven Schmitz

Yes, absolutely. And I’ll let Mark speak to it because it's not like any other wind tunnel. It's, you know, a unique facility that Mark has been building here at Penn State. And it allows us to do some really new innovative things.

Mark Miller

Thanks, Sven. It's kind of, like I mentioned, a little bit different of a facility than you would normally think of, like a kind of a wind tunnel with a fan and a small test section to put small models in. The main difference is we built this tunnel inside a pressure vessel. So what that allows us to do is basically fill the vessel with compressed air to sort of any pressure, and it goes pretty high. So we can go up to about 500 psi, which is 34 times atmospheric pressure.

And the cool thing about that is the pressure really counteracts the small-scale size of a model. So if we made like let's say a ten-inch diameter rotor, right, that we put... So it's very manageable size, and we put it in this 500 psi environment, and then we have a fan inside that pressure tank that moves the air around, that creates the wind tunnel element. And that essentially will recreate the exact aerodynamics of a 30-foot diameter rotor. So there's a pretty powerful scaling, you know, thing that we can do where we can compensate for the small size. Because typically when you make something ten times or so, even five times smaller than the full size, the aerodynamics will not match.

So you could do a small experiment unless you're really careful. You know, you have to be well, you have to be extremely careful or do some simulations to take that information and extrapolate it up to a large scale. But we don't have to do that at Penn State. We can actually simulate directly very large-scale things. And a 30-foot diameter rotor acts much more similarly to a 90-foot, right, than, let's say ten-inch rotor acts to a 30-foot.

So, there's a big change when you go from that really small ten-inch size at atmosphere up to 30 foot at full scale. So, we kind of get the best of both worlds when it comes to the scaling ability of this tunnel.

Host

So let's jump into these floating offshore wind turbines. Can you tell us about them?

Mark Miller

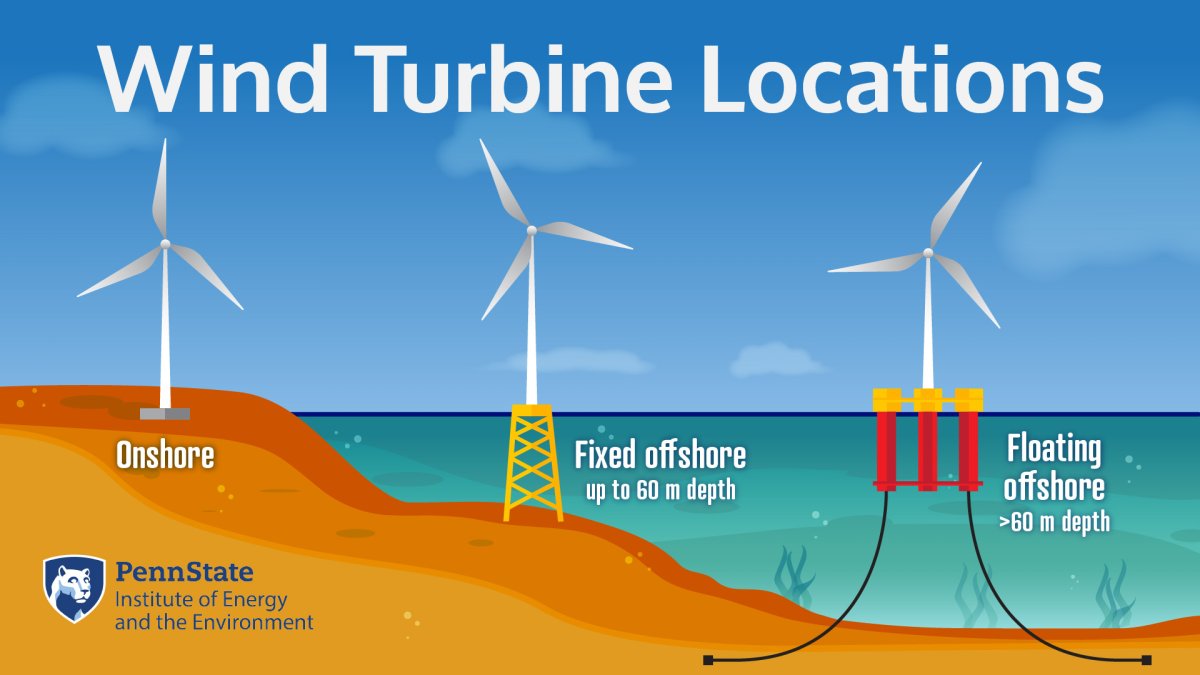

A floating offshore wind turbine is essentially the idea is we can take sort of a traditional offshore turbine, and typically those are fixed to the ground. So, we take these big steel pylons basically and drive them into the seabed and mount a turbine on top of a platform outside of the water. So, they're not going anywhere. Right? You're fixed in place. It's obviously a lot simpler too, because your turbine is not going to move a whole lot. It's not really affected too much by the waves, ocean state, things like that. But the idea with floating is that we kind of get rid of the fixed element, and now we make sort of a buoyant platform so that it's literally floating in the ocean.

And the reason we want to do that is basically because there's a lot of places where the water is just too deep to do a fixed base. So we're talking hundreds of feet to thousands of feet deep. And this can occur actually in a lot of places, usually really far offshore on the East Coast, but especially in the U.S., on the West Coast is a really promising area for offshore wind. The problem is it is really deep there. So this is where floating technology comes into place.

Now from a kind of other perspective, as we'll talk about, there's a lot of challenges that come when you try and make something as big as a wind turbine float. You know, for reference, these turbines can be over 200 meters. So more than two football fields in diameter, so the rotor diameter itself.

And then they’re typically at least you know, they have to be at least 150 or more meters up in the air as well. So they're very tall structures. So this is going to create problems when you, you know, have not only you're trying to make that tall structure float, so you're kind of balancing it vertically, but you also have kind of the waves and interactions and sea motions you have to sort of worry about now. As well as the aerodynamics, right? So you have, you know, the flow coming past. You might have turbulence or hurricanes, which put a large load on your turbine. And that also will try and upset this sort of delicate balance of making a floating vessel, basically, or a floating platform.

The offshore floating is very much in the prototype development stage. There's no that I know of any existing farm of these anywhere. There's a few kind of like one-off test turbines that are typically much smaller than what you would do on a fixed platform. So we're talking tens, 50 meters maybe, but nothing is big. Now, in the future that probably will change, right? So you always start small, especially in wind energy where you know you want something that's very reliable, long-lasting, and also economical.

So as these... as we gain more confidence in these floating platforms and our ability to install them, it's likely that they will also get bigger, just like the fixed platform offshore. But we're looking kind of pretty far down the road for that to happen. But, you know, broad strokes: the Department of Energy in the United States is very pro floating offshore wind platform development because we have such a big resource right in the U.S., especially on the West Coast of these deepwater areas where this could be used if it was, you know, cheap enough and reliable enough.

Host

So you've said the future, is there any idea of like what we're talking about? Are we decades away from this at this point? Is that realistic to think through?

Mark Miller

I think the best way to look at it right now, at least from a very practical point of view, there's a lot of interesting sort of technology questions there that we're interested as, as engineers and scientists. But from a practical point of view, like what gets these in the water, in my opinion, it's all about costs, right? So if you can get these things to where they're competitive with fixed platform or maybe even a little more expensive, but you can use them in these deep-water cases where you just don't have any other option? Then it could be really attractive.

So, to give you some numbers we use in wind energy a lot this cost per megawatt hour. So, it's sort of like the cost per amount of energy that you use or buy. Right? And you know, fixed right now, installed in 2021, fixed turbines are about $75 per megawatt hour. Just kind of give you an idea. Whereas floating they're only estimated, these are all estimated numbers because we don't have any floating farms, but they're about three times that.

So those numbers don't really add up, even when you have a special use case, like really deep water. There has been some work trying to project when this would occur. And a lot of groups, it really depends on who you ask. But some of the papers have said in 2035 that 200 and... so let's say we had $75 per megawatt hour for fixed, you know, by 2035, that probably would come down to about $53 per megawatt hour. Just because even for the fixed, the stuff is getting cheaper. They're getting more common.

Now for the floating, that would start out today, about $207 per megawatt hour. That would come down to about $64. So you're talking in 2035, let's say 10 to 12 years from now, right between there, you know, you're looking at some projected parity on cost.

I was just going to add some more, a little bit more context to some of those numbers. You know, if you're wondering in the audience like what are these $70 per megawatt hour.

So if you're buying today, for instance, if you're buying your energy from a, you know, gas turbine power plant, it's actually about the same as some of those offshore numbers, maybe a little bit cheaper. So about $62 per megawatt hour. If you buy your energy from a gas-fired plant. Interestingly, onshore wind, where we don't have to worry about, you know, the marine environment or building things off of boats, right, which is quite a bit more difficult. So onshore wind is quite a bit cheaper. You're going to pay typically about the $50 per megawatt hour. Could be higher in some places, could be lower in others, like if you're in for instance, some parts of like Texas or out West where they have a lot of wind, you could pay significantly lower energy prices compared to like gas turbines and things.

So just to give you an idea, you know, one of the neat things about wind is that it has come down in price so much. So the reason I mentioned this is there's reason to believe the same will happen with floating, because we've been able to reduce... well, the industry has been able to reduce the cost of onshore and offshore significantly in the past couple of decades, really, so that that's only really accelerating, too.

Host

For those of us who may not be familiar with... we hear all these energy terms... megawatt hour.

Mark Miller

It's really a unit of energy is what you could think about it as. For instance, you know, one megawatt itself will power around 700 homes if you want to think about it that way, a lot less if everyone's using air conditioners, right? So it could be like 300 homes in the South, but it could be 700 to 900 even in the North. And one megawatt hour, so the hour part basically means you could power those 700 homes for one hour.

Host

What's the reason that we're pushing to have offshore wind at this point?

Sven Schmitz

Why are we pushing offshore wind at this point is a good question. I think part of the answer is that most of the good onshore wind sites have been already taken, and there's just a larger wind resource available offshore. It also doesn't interfere right there with, you know, much with, you know, biology in general. Right? Except for, you know, the, the, the marine environment and, it doesn't interfere with, with, with people as well.

So that's, that has become a big problem. And in Europe, these large rotors, they make noise. And onshore you also have transportation limits. So what you can do offshore is you can have larger rotors, longer blades, and you can run them also faster, which increases the efficiency. And, if you run them faster, they make more noise. But if you're offshore, it doesn't annoy anybody. And so you don't have these, these kinds of restrictions.

Mark Miller

Another reason to add on to what Sven said, which is kind of right, we have we have a huge amount of population near the coasts, which is where we use most of our power. So generating your power, where you use it, is also very beneficial. So this is another advantage in addition is that we can produce power where we use it, right? We don't have to transmit it across big, long transmission lines or anything.

Host

So I know you started to talk about floating offshore wind turbines and the challenges around cost. Can we dive a little further into cost, or maybe even explore some of the other challenges around floating offshore wind turbines?

Mark Miller

The actual turbine itself, for most floating platforms is generally the same as a fixed platform turbine, and that's one of actually, one of the key parts of our work is to look at the floating turbine as a system and not just different components, right? So they kind of think, you know, we build this fancy floating platform and we just sort of stick a regular, quote unquote, offshore fixed foundation turbine on it. So we take what we already know. We know these turbines work on fixed platforms. We just move it to this floating one.

But there could be some very key benefits to reconsidering the system as a whole and looking, you know, could we do something different with the turbines, maybe modify them a little bit, build them slightly differently so that they interact with the platform in a beneficial way, or that we take into account some of the more restrictive parts of the platform. Maybe make the platform a little cheaper by maybe producing a slightly different turbine, right?

So you're really optimizing the entire floating offshore turbine instead of just kind of combining parts, right? So that's really one of the main motivations for some of our work, at least from my perspective, is if we can sort of use some, some clever new turbine designs, then maybe we can help reduce the cost of the overall system, and also consider things like the structure and the platform as part of this equation, right? So it's a little multifaceted, I guess.

Sven Schmitz

Yeah. So one of the aspects that that we are looking at is, is to do a bit more clever aerodynamics for these rotors. You know, humans have the habit, if they go in and found the resource, they tend to exploit it the best they can. So usually wind turbine rotors are designed that for a given wind speed, they take out as much power as they possibly can for the wind. And so we are rethinking, this a little bit. And so one of the concepts we are looking at is the so-called low-induction rotor. So what it means is that you actually design an aerodynamic turbine that does not maximize power. And so you're sacrificing actually a little bit of power capture.

But at the same time that also reduces the aerodynamic loads on the structure. So if you do it you can actually, you know, make all the foundation less heavy, less expensive, less complex. And all of that comes together in and what they call in wind energy, the levelized cost of energy equation where, where, you know, the capital investment of the turbine is, you know, at some point proportional to the amount of carbon fiber and steel you are using for everything.

So if you sacrifice that little bit of power, you actually have a higher gradient in reducing the loads and hence the total material that's needed to build the turbines and make it operational. And that is really where we come in. And we have found already some, you know, clever, clever new, engineering relations there that, that kind of, put this all together.

Mark Miller

Yeah. It's, I think, efficiency actually is a very good choice of words here, Kevin, because that's the way we think about turbines. But now we're basically redefining efficiency, taking into account the structural demands of the turbine and the foundation. So it's really a new... sort of a new objective in our optimization, right? It's not just “we're going to make as much power as we can, with what we... what's available.” We're actually sort of really redefining what the optimal point is based on this low-induction rotor concept, if that makes sense.

Sven Schmitz

So, it's a shift in, in paradigm, right? Instead of thinking, “oh, I generate as much energy as I possibly can because I can sell it.” The real or levelized cost of energy comes from a different, you know, balance between how much power you produce, but also how expensive your entire system was, how many resources, right? And CO2 impact came into there.

And also what's the operations and maintenance? If you work the turbine too hard and your structure loads are higher, right? Your lifetime and your fatigue cycles are also higher. And so that affects that part of the levelized cost of energy equation as well. So it's really, I think we have an innovative edge here, where we are trying to combine those and balance those out that actually if you know, you generate a few kilowatt hours less with a given turbine, the price of generated energy is actually a lot lower.

Mark Miller

This sounds like it could be beneficial to a lot of different turbines, maybe not just floating. The reason we're targeting floating, though, is because of how critical the aerodynamic loads are to what you need for the floating structure. So the floating platform, not only like a boat, has to be buoyant enough to support the weight of the turbine, it also has to counteract the sort of toppling-over force that the turbine generates.

So when you extract power from the wind, part of that is you actually do need to slow down the incoming wind a little bit. And by doing that, you're sort of making a big drag on your system, right? And so that force is always trying to push over your wind turbine tower and kind of bend it over towards the ground, right, and break it. So you have to really take this into account. And that's another big benefit of combining this low-induction rotor that Sven’s working on with the platform element, is that you can really downsize the amount of sort of buoyant structure that you need because you have less overall thrust to deal with.

So not only is your wind turbine lighter and cheaper to produce because the materials cost is a big part of that. It also has less of a sort of toppling-over force on the platform, so it makes it extra advantageous to these buoyant type platforms, if that makes sense?

Host

I don't know if this is even reasonable to ask you two this, but I have to think, how do these things not float away? You've already spoken to the idea of not blow over or fall over, so you're thinking about that already. But I'm thinking about in hurricanes and, you know, extreme weather and movement throughout the ocean. How do these things not end up in Greenland?

Mark Miller

Yeah, the floating nomenclature in this case is... it's really a what you call kind of a moored structure. So these things are not free floating. It's not you know, it's not like a boat, right? They're not meant to move around in the ocean. They will moor them through many different methods. But basically, what that means is they have these big, long cables with anchors into the seabed. So, you know, it's much cheaper to make a couple of big, long steel cables underwater and an anchor than it is to make a 200-foot-long steel fixed base. So there still is some underwater structure tying it to a certain location, but those are really just to locate it kind of on the surface. They're not providing, you know, anything else other than sort of an anchoring mechanism, if that makes sense.

Host

So what is your team doing to make them more commercially viable?

Mark Miller

So from my perspective it's about reducing all of these unknowns, right? So let's especially when we come to our system which is even, you know, a little bit farther as far as the sort of technology level than it is just taking an existing turbine and sticking it on a platform. So what my thought is we do a lot of simulations and experimental testing of representative cases and do those at conditions that really matter.

So, you know, do them in this special wind tunnel that we have with conditions that they would realistically see out in the field, and then compare that to our simulations that Sven is working on, and incorporate some of the new structural elements. So we're kind of looking into those areas right now. But really the goal is just to reduce the uncertainty and provide more information to people who may be designing these new floating platforms or looking for comparison data for their own, you know, model building and simulations.

Sven Schmitz

Yeah. And we've talked a lot about a single floating platform, but it also becomes a lot more interesting if you, Kevin, as you mentioned before, if you have a farm of those. So they're not really independent of one another because the wake of an upstream turbine interferes with the performance of a downstream turbine. You know, I mean, if you play with a little propeller toy or something, you feel this kind of inflow or downwash that it generates and it generates some vortices too, and they propagate far into the wake and they, and they change the inflow to the downstream turbine.

So one, one open research question is always about the scale. My God, these, these machines, they are ginormous. And, you have these large vertical wake structures that emanate from one turbine and they interact with the next one. How do we design a properly scaled experiment that we can predict how is that going to affect the full-scale performance?

So here again, we as part of this project, we played with the basic equations. We did some math. And so we developed the wake-scaling methodology where we can actually scale these wakes from 100-meter blades down to a point one meter blade, almost a thousand scale down, to test in Mark's facility. So we already built a rotor that looks different than a wind turbine. It's more solid, but... so this is one of the first experiments I think we will do then, this summer. It all works fine in the simulations. It scales exactly to the way it has to. And, and I think we are hoping, right, by the end of this seed grant, we have a first experiment that actually confirms that. So that could be a little bit of a game changer in the field.

Mark Miller

The goal of this seed grant, is to sort of, yeah, like Sven mentioned, do a really nice proof of concept of the combined simulation experimental approach with unique tools on both sides to tackle a really hard, integrated problem of turbine platform foundation structures. So that that's our ultimate goal is to just... We don't have quite enough room to solve every problem with floating offshore wind, but we can kind of dip our toe in and do a really nice proof of concept of this new idea.

And that's what I kind of view a lot of our job in the academic setting is, you know, we're looking not just five years ahead. That's kind of what industry is doing, five to ten years. We're looking past that even. So, you know, we're looking kind of into the future. What's the future turbine design going to potentially look like.

Host

So with all this knowledge you're producing, who are some of the people that are going to benefit from this?

Sven Schmitz

Well, I think, you know, wind turbine designers and manufacturers, they would be quite interested in this because whatever we find here and publish, we’re going, as I said, to change a little bit to have a paradigm shift here. This is, you know, how wind turbine blades were aerodynamically designed until now. Here’s something else. That's what we are for in academia. But we will disseminate these findings. And I think they will be picked up.

Mark Miller

Yeah. And if you look 30, 25, 30 years ago, the idea of doing a floating offshore wind turbine would have been considered kind of crazy, right? So these things have a way of becoming mainstream, right? Once there is these new ideas and proofs of concepts that are out there, I think we both kind of view that as our job with this project is really proof that this method we're coming up with has practical uses and will work by giving these data sets and making them freely available to other people to use and look at.

Host

Can you talk about next steps in your project?

Mark Miller

Currently, we are, at least on my side, working on testing this turbine. Like I said, we have this very new wind tunnel facility. It just came online in February of this year. So we've been processing through quite a lot of experiments and, oh! Very soon is the test the first test of this low-induction rotor. So we're not going to be simulating any of the floating foundation or anything like that. We're just going to be looking at can we match the performance of the turbine in the tunnel that we predicted or that Sven’s group predicted? And can we also match the wake characteristics that we set out to match? So kind of a very, you know, first pass run. So that's kind of the near-term next steps on our side.

Sven Schmitz

Yeah I mean it's really, you know, this IEE seed grant enables us to get some preliminary data on a really crazy idea. And so if we, you know, have that preliminary data, then we can really, you know, we will go to NSF and DOE and write a couple of proposals and say here we actually have already, you know, supporting material that that this can work.

Host

This is fantastic. Well, thank you both. Thanks so much for taking time and discussing this. It's exciting to listen to and hear about these groundbreaking things that are happening at the University.

Mark Miller

Thank you for having us, Kevin. It's nice to have this platform to talk a little bit outside of our regular academic channels, especially. I think it's important that we continue to maintain this communication and all the interesting things that, well, we think are interesting. Hopefully everyone else does as well, that we're working on. Yeah. I guess, if you would like to reach out where I would obviously be always be open to the collaboration. We have this new wind tunnel tool that's very good at testing things at full scale, but for very low cost, because you only need small models. You can find us at fluids.psu.edu, if you'd like to contact me or my lab.

Sven Schmitz

Thanks for having us, Kevin, today. It's nice to try to explain what we do to the broader IEE community. And so, wind energy has not often been, you know, part of the seeds. And so we hope, we hope that opens a little bit the door also for further collaborations here. So thank you.

Host

You are very welcome. I appreciate your time. Thank you so much.

This has been season four, episode 12 of Growing Impact. Thanks again to Mark Miller and Sven Schmitz for speaking with me about their project. To watch a video version of this episode and to learn more about the research team, visit iee.psu.edu/podcast. Once you're there, you'll find previous episodes, transcripts, related graphics, and so much more.

Our creative director is Chris Komlenic, with graphic design and video production by Brenna Buck, and promotional and social media support by Tori Indivero. Join us again next month as we continue our exploration of Penn State research and its growing impact. Thanks for listening.