26-minute listen/watch | 14-minute read | 1-minute teaser

Cement, a major component of concrete, is a significant contributor to global carbon emissions. Researchers are exploring agricultural waste as a potential alternative to cement, aiming to reduce carbon footprint while also finding new uses for farm byproducts. However, the feasibility and effectiveness of this solution depend on the collaboration between researchers and farming communities.

Transcript

JP Gevaudan

In this project we were really excited to think about, well, how can we actually create cement replacements so that we can produce concrete that is sustainable?

Host

Welcome to Growing Impact, a podcast by the Institute of Energy and the Environment at Penn State. Each month, Growing Impact explores the projects of Penn State researchers who are solving some of the world's most challenging energy and environmental issues. Each project has been funded by the Institute's seed grant program that grows new research ideas into impactful energy and environmental solutions.

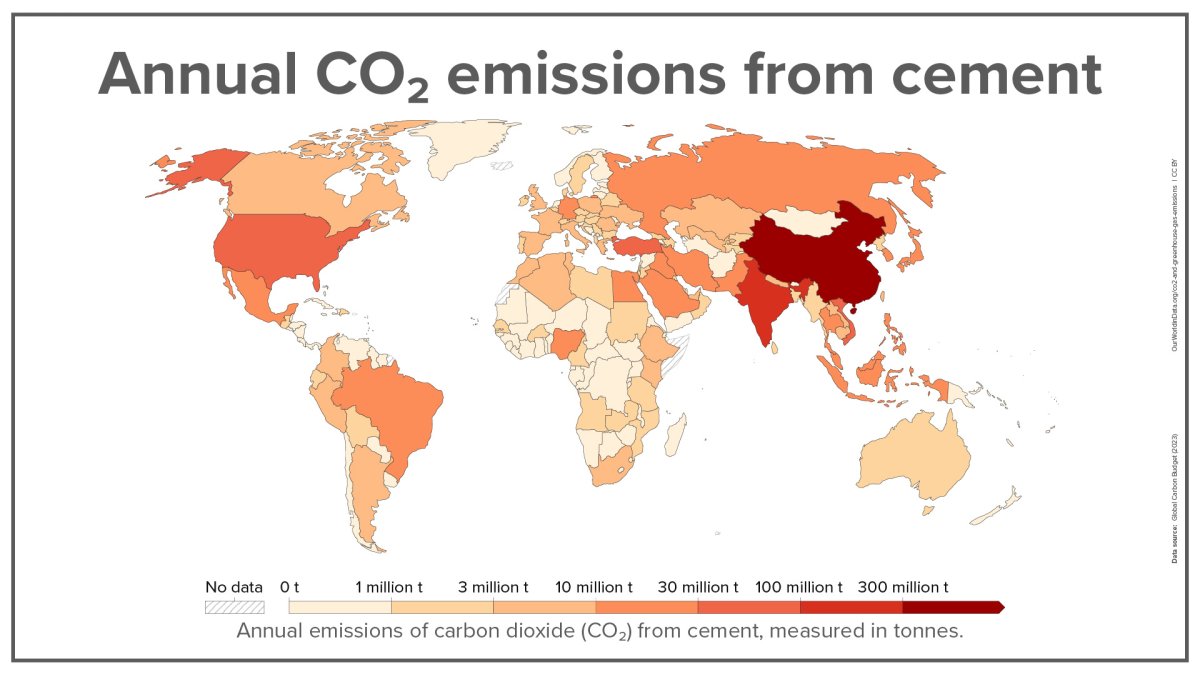

I'm your host, Kevin Sliman. As the world continues to grow and develop, more and more concrete is used. Cement, the component in concrete that glues sand and crushed stone together, is one of the most energy-intensive products in the world to produce. Between the use of fossil fuel-fired kilns to the chemical reactions that take place in concrete, the carbon emissions add up to almost 10% of all human CO2 emissions.

On this episode of Growing Impact, we discuss cement replacements that could be obtained through agricultural waste. But as we'll learn today, what some see as waste, others see as a commodity. So, our researchers are working with farming communities to see if and how crop remnants might be a path forward in the pursuit of carbon-friendly cement, and how the process can be beneficial to farmers.

Thank you, Kaitlyn and JP. Thank you for coming on and talking about your project. I really appreciate you taking time and talking with me.

JP Gevaudan

Yeah, we're happy to be here.

Kaitlyn Spangler

Yeah. Thank you.

Host

Can you tell us your name, your title, and a brief background on your research?

JP Gevaudan

My name is Juan Pablo Gevaudan, but I realized, ever since high school, that that was a bit of a mouthful. So, JP works. I am an assistant professor in the architectural engineering department. I'm also affiliated with the Materials Science and Engineering Department here in Penn State, and our research really encompasses the decarbonization of concrete materials and how we can actually achieve that through technologies that we're going to discuss today in the podcast.

Kaitlyn Spangler

I am Kaitlyn Spangler. I am an assistant professor in the Department of Agricultural Economics, Sociology, and Education. We're basically the social science arm of the College of Ag Sciences at Penn State. And a lot of my research thinks about how and why we diversify agricultural landscapes, how farmers make decisions about what they do with their land, and how those landscapes are mechanisms for building community, community development, and sometimes how they're not.

This research kind of integrates a lot of that, a lot of those elements of how and why farmers do what they do on their land, and what it means for broader rural communities.

Host

You're working on a project that is taking waste from farms, and then using it to create an ingredient for cement. Can you first, can you tell us about what kind of waste it is that you're working with? And then why is it important to focus on this?

Kaitlyn Spangler

We've sort of framed what this waste is as basically the stocks and leaves. It's called “stover” for corn or “straw” for wheat. The stocks and leaves that are left over in the field after that main crop is harvested. If you're growing ear corn, corn for grain or sweet corn, rather than corn for silage, which is basically kind of like a hay mixture. If you’re growing corn, ear corn, you cut the ears off, and whatever is left in the field is this sort of stover piece. So we framed it as waste. And as we've quickly learned from reading published literature and also some preliminary interviews, is that it's actually not waste.

And we're sort of learning about what all the other on-farm and off-farm markets and uses are for the stover and straw. And what this project means in the context of this, this larger conversation. So I think it's sort of step one is actually figuring out what is waste. And if it's not waste, what does it mean for the potential for using this kind of byproduct for cement and other uses?

JP Gevaudan

It is important for us to remind ourselves and realize that cement production accounts for between 4 and 6% of CO2 emissions globally, right? So when we're thinking about decarbonizing our industry and our society, we really need to look at the impact that cement as a component of concrete has in our world, right? So in this project, we were really excited to think about, well, how can we actually create cement replacements so that we can produce concrete that is sustainable?

When we look at, you know, the United States low-carbon concrete production, the main... one of the main methods to create low carbon or sustainable concrete is by using cement replacements. Right. These materials allow us to reduce the amount of cement which emits so much CO2 in our world. And usually we can use things that are industrial byproducts of different industries, whether that is the coal burning power plant industry or perhaps the steel manufacturing industry.

And this case, we wanted to understand well, could we look at some of the residues or byproducts of the agricultural industry?

Kaitlyn Spangler

You know, if you work in ag, it's impossible not to talk about corn, soy, or wheat in the U.S. We grow upwards of 70% of all of our cropland, in the US., harvested cropland, is just those three crops. It takes up... We have an incredibly simplified and specialized system, and we know that it's really important to diversify what we grow, that we've created a lot of problems for ourselves by just relying on a small subset of these crops.

But the fact of the matter is that if we're looking for waste or byproducts from agriculture, it makes a lot of sense to start with crops that we have a ton of, because that way, you know, if we can find those circular pathways to use whatever is waste or whatever is left over, then we can have a lot of it pretty quickly. So this is sort of part of that conversation of how we do this sustainably and how we do it well.

JP Gevaudan

One thing that I wanted to add to that is that this idea is coming from the push in our nation to grow the bioeconomy, and what the bioeconomy means is how can we utilize biological matter that either we grow or we leave on the field, or we consider as a residue or a waste? And how can we use it to create new products, whether that is aviation fuel, whether that is ethanol, or maybe that is something else, such as in the case of our project, which we're thinking, well, could this be cement replacements? How could we engineer our process so that we can understand them as or create or engineer their properties to be good for us in their replacement?

So I think that is really important. And, you know, just to put some numbers into the amount of crop residues that we generate every year in the United States, it's about 279 million tons of crop residue. Now, a large part of that is corn stover, just because of just the sheer amount of corn that we grow in the United States. But, you know, from the literature, the research that we have done, it is important to note that not all of that crop residue is something that we're advocating to be harvested or collected from the field when we're thinking about sustainable practices in agriculture, we actually want to keep some of that crop residue in the field so that the carbon cycle and the soil carbon, specifically, is not negatively affected.

Kaitlyn Spangler

Yeah, we're not losing carbon, at unsustainable and accelerated thresholds.

Host

So with this preliminary data that you found, is it changing your project and if so, how is it changing your... either way you're thinking about it or approaching it?

Kaitlyn Spangler

I'm actually really excited that we get to talk about this project through the lens of a seed grant, because I think it sort of embodies exactly what a seed grant can and should do, is that it provides this exploratory space to build something bigger and do it better. So, so far, we've interviewed a handful of farmers. I think we're around five or six right now, and also an agricultural consultant.

So that's something that we're going to continue growing is interviewing more farmers. And we focus specifically on Pennsylvania so far, which is also something that we might expand on with more money and more time. But in talking to those farmers, we quickly sort of realized and found exactly what we were finding in the literature. The farmers expressed a hesitancy to take the stover or the straw or whatever this residue off their field, because it sort of, it acts as this natural mulch that sort of keeps the ground cover covered, prevents some soil erosion. And we sort of find evidence of this in the literature that it does. It does something for the soil, provides the organic matter.

But also if they, if farmers have animals on their farm, if they have dairy cows or beef cattle, etc., they'll harvest what they need from that stover, bale it, and use it in their hay barn, so they'll use it for maybe adding to their feed, or they'll use it as bedding. So right now we're actually just trying to characterize what are all the uses for this residue and what are the ways that it's not waste, because if it's if it is waste, it's essentially just chopped in the field and it lays there and then it hopefully decomposes at a rate that's useful, which is something that we can come back to.

But if it decomposes quickly enough, it adds the organic matter to the soil, and they can plant right into it. There's a little bit of nuance there, like how that works and what farmers, you know, if that actually happens every season. But that's the goal. And knowing that there is this hesitancy, even if we have, we say that, well, there's actually a lot of evidence that we can harvest, let's say, between 30 to 50% of this stover without negatively impacting soil. We're still seeing farmers be like, I just rather not. And I think a lot of that is that there's not an established market for this stover in Pennsylvania.

So this is helping us pivot. Okay. So it's not this readily available waste source. We know that pretty pretty confidently. But I'll just offer this and then I'll sort of pass it to JP is that one farmer did mention that if he takes off his stover or his straw, he sees it as a way, you know, he wants to get it back on his field. So if he takes a stover or straw off, he sees it as a way of recycling through the hay barn, where if he feeds it to his cows, his cows produce manure. He sprays or applies his manure onto his field. He's essentially getting those nutrients back that he took off, and he just sort of recycled it through the hay barn.

And I think this is a like sort of a metaphor for our pivot point of some of the new directions we might go, and I'll let JP explain what those are.

JP Gevaudan

We're inspired by this story of this farmer. Right. And the idea here is that, well, what if we can take the corn stover and put it through our technology such that we make that corn stover better for applications like refining that corn stover for a biofuel, aviation fuel, or ethanol. Yet we can extract the mineral nutrients that the farmers are hoping to put back into their fields from that corn stover in the first place. Right? So in that way, we're servicing two different functions, right? We're not only creating that bioproduct, whether that is aviation fuel or ethanol, but we're also meeting the worry or the challenge that we have found in our findings of that, farmers really seeing the loss of nutrients from their soils as a big obstacle for removing that crop residue in the first place.

So that's the direction that we're very excited about. Of course, you know, there's always a question about, well, this mineral nutrient. Well, a lot of them are... is potassium right. And what other things can we do with potassium. And of course, you know, being a cement chemist, one of the things that we want to explore as well is in addition to perhaps making this a mineral nutrient for the soil, can we also look at it for some of the cement applications where we need that potassium to create innovative cement?

Host

What process does the plant waste or the residues, what process do they go through to sequester carbon?

JP Gevaudan

Our technology, something that we have developed here at Penn State, and we like to call it mechano-carbonation. And what that really means is that we can put the corn stover in this reactor, and what this reactor will do is that it's going to flow CO2 that we can capture from our own power plants here at Penn State, and that CO2 is going to be locked up by our technology to the components that are inorganic in the corn.

Corn actually has a lot of potassium, silica, some sodium, and calcium. These are things that are usually found in soil. And the crop residue, corn, will just, you know, accumulate a lot of these in its biomass. And what we can do is use all that inorganic material and lock CO2 in it. And extract it from the corn stover. That's what we call the mineral nutrients. That's what the farmers use to fertilize their soil.

The other thing is by removing some of those mineral nutrients, we actually also remove some lignin from the biomass. What we find from the research and the literature on these integrated bio refineries, especially some down in Georgia, where they are creating aviation fuel, is that this sort of pretreatment to remove the mineral nutrients or the inorganic component of corn stover, as well as some of the lignin, is something that they're already doing such that they can produce aviation fuel more efficiently.

So we believe that our technology (a) is simpler in some cases than some of the ones that are used in this by refineries. But it can also lock away carbon in that process, which makes it a carbon neutral or potentially a carbon negative pretreatment technology to create two bioproducts: the mineral nutrient, as well as that corn stover for biofuels.

Kaitlyn Spangler

And we're sort of offering a potentially, a more efficient and better way to do this, and one that actually explicitly considers what farmers go through in deciding whether or not they want to take off their stover.

JP Gevaudan

Just rough numbers. Some of the CO2 sequestration that we can achieve is about 3 to 5 weight percent per dry weight basis of that corn stover. So that's what we are targeting in terms of CO2 sequestration. And when you look at the IPCC report on global climate change, one of the biggest areas for improvement to abate global climate change is by increasing the carbon sequestration in agricultural systems. So we believe that our technology can contribute directly towards that CO2 sequestration in the United States.

Host

With the mechano-carbonation process, it's creating this mineral heavy ash, am I understanding this correctly? Inorganic, I guess maybe I should call it, is that the right way to say it?

JP Gevaudan

Yeah. Think about it, that we are extracting the inorganics through the process, and we're creating two streams. So one is with the inorganics and the other stream is the corn stover that has been treated. So the inorganics will be what's being looked at by, by our project and to its potential for a mineral nutrient or whether it can be a component for this innovative cementitious materials, which are my bread and butter, which are named alkali activated materials.

Host

Let's talk about the inorganic side of it first then. Tell us about these applications like so. Oh, definitely talk about the cement. I mean that's clearly the original intent of this. Let's talk about the cement and what happens to this ash as a result of the process, and what can be done with it.

JP Gevaudan

When we're thinking about cementitious materials, and particularly this new class of cementitious materials called alkali activated materials. Well, these are really interesting for us because we can actually take an industrial byproduct, let's say slag from the steel manufacturing process. And we can add some potassium carbonate, right, from our process. The same powder. Right. And now we can, you know, add water and that mixture right there, can be a replacement, complete replacement to portland cement that we use today to create conventional concrete. Right. So in essence we have produced an alternative cementitious material that can be made entirely out of industrial waste or byproducts. And that's really, really interesting. You know some of the lifecycle analysis literature for these alkali activated cements say that we can lower CO2 emissions in comparison to conventional portland cement concrete by 90%.

So now we have produced not only a material that is 90% less CO2 than conventional form cement concrete, but now it's coming from byproducts and waste from the United States. When you start looking at the global South, countries that have primary, primarily agricultural sectors and industry, well, they're not... they don't have as many abundant sources of industrialized byproducts.

You know, they rely on these huge agricultural sectors. So our technologies can help, hopefully, these countries that have large agricultural sectors to produce either cement replacements or materials that can be alkali activated to produce concrete that is sustainable and have lower carbon emissions. So that's the international component that I also get excited about, because it also allows for sustainable development to happen in the areas of the world where we expect most of that development to occur due to urbanization trends and population growth.

Host

So a question about the actual technology. I didn't ask this in the beginning. Is this something that is unique to you and your lab? Is this something that was developed by you or this, yeah?

JP Gevaudan

Yeah, yeah, this is this is an invention that we have pioneered in my lab. And I am lucky to be working with some amazing, bright graduate students as well as two engineering laboratory technologists. So it's a team effort. And we're very proud to be one of the first labs to have this technology.

Host

So how can this benefit the farming community? And could you maybe talk about how it could benefit the built environment?

Kaitlyn Spangler

What's exciting is that we don't necessarily know yet how it can benefit the farming community and what... who those communities are. So what we hope to do and what we plan to do with the seed grant and hopefully future funding. You know, right now we have a solid like 20-year trajectory with all the questions we want to answer. But right now it's mostly based on interviewing farmers. And what's cool is that we've actually been doing sort of team in sort of mixed-team interviewing. So I'm the social scientist, but we have a grad student from JP's lab, Dia Brown, and JP as well, that we've been trying to conduct these interviews together or however we can manage it, which is really cool.

But basically right now asking farmers what they're doing with their crop residues, what they see as feasible, and are there sort of gaps and benefits that could be filled, like finding a way to sort of prepare the mineral nutrients that they need for their field in another way, if they can take their stover off. So that's an example of hopefully a benefit. But we hope to continue talking to farmers across Pennsylvania. Again, this sort of spectrum of smaller sweet corn farmers to larger industrial corn-for-grain farmers and other farmers in between.

JP Gevaudan

From the built environment side, I think there is multiple benefits. The main benefit, for both the built environment and the agricultural sector is the decarbonization potential that this technology has. So right now we are engineering the process to verify the carbonation sequestration efficiency of our technology. But we hope that we can achieve around 28 million tons of CO2 annually to be sequestered through this process.

So beyond carbon sequestration, of course, but the secondary benefit is really contributing to a circular economy by producing these components of alkali-activated materials or mineral nutrients that we can give back to farmers such that they can replenish their soil with those nutrients that corn absorb throughout its growing process.

Host

Let's talk about next steps for the project. What are you excited about? Or maybe some challenges?

JP Gevaudan

Yeah. So I think one of the things that, you know, we're very excited about is definitely this carbon sequestration potential. Right now, we are in the process of actually quantifying what the carbon sequestration is, and that's going to allow us to optimize the process, because as we have developed this technology in my lab, we still don't necessarily understand, or we're not at the point of really optimization. Right. So a lot of this data that we're gathering, is going to be really, really helpful to not only understand it from a fundamental perspective, but then to also optimize it.

Kaitlyn Spangler

Yeah. And I think as you sort of mentioned across the conversation, is that we're really in an expansion phase. So talking to more farmers and other stakeholders in different rural areas right now in Pennsylvania, considering other places as well, and then also bringing in other folks in this sort of agronomy space to actually think about making this, the byproducts useful to farmers.

Host

Thank you so much for being on Growing Impact, both of you, JP, Kaitlyn, thanks for coming on and talking about all this research. It's exciting to hear.

JP Gevaudan

Yeah, well, thank you so much for the opportunity to talk about our research. And we're very excited. So this has been great.

Kaitlyn Spangler

Yeah. Thank you so much.

Host

This has been season five, episode four of Growing Impact. Thanks again to JP Gevaudan and Kaitlyn Spangler for speaking with me about their project. To watch a video version of this episode and to learn more about the research team, visit iee.psu.edu/podcast. Once you're there, you'll find previous episodes, transcripts, related graphics, and so much more.

Our creative director is Chris Komlenic, with graphic design and video production by Brenna Buck, marketing and social media by Tori Indivero, and web support by John Stabinger. Join us again next month as we continue our exploration of Penn State research and its growing impact. Thanks for listening.